1,100,000 lbf Hydraulic Preload Press for Fusion Experiment

At the Center for Electromechanics, we built a 1/16 scale prototype of a toroidal magnet for a fusion Tokamak- the program was published under the "IGNITEX" name. The magnet was a single-turn design, built from thick copper wedges that came together to make a toroid shape surrounded by a solid copper conduction path. The magnet drew 9 MA from six generators in parallel, and it developed 20T on its central axis (a world record flux density) for 1/10 of a second. The EM forces from the high current caused high circumferential compressive stress in the magnet's throat- but the Von Mises stress was controlled by exerting a high axial compressive preload. In other words, we squeezed it axially to keep it from flying apart.

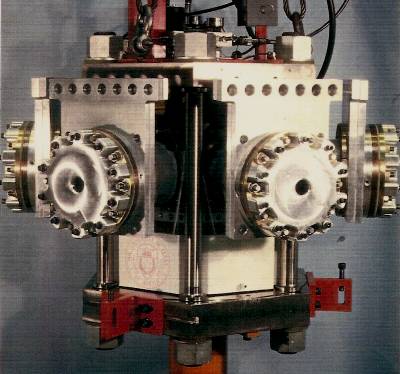

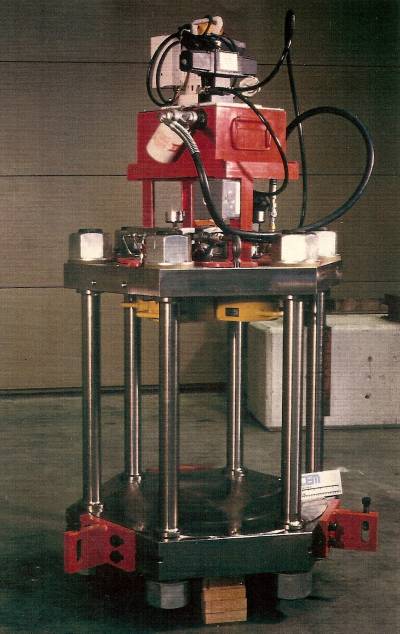

The preload press itself (shown at right) had to be compact enough to fit into a crowded underground facility filled with generators and buswork, had to have its own hydraulic system, and had to have a leveling system to allow alignment with the toroidal magnet. It was made from two thick 4340 steel platens and six vertical links, all of which had to be lowered into a pit and assembled by hand in close quarters. The hydraulic system (painted orange) was then lowered onto the top platen.

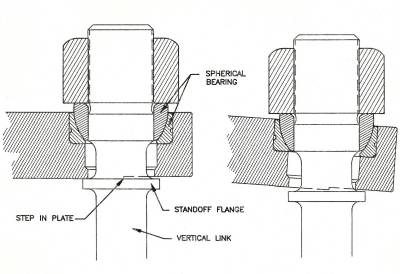

Because the platens would flex considerably at maximum load, the joints between the links and the platens were designed to pivot. Spherical bearings were used at the end of each link to manage bending stresses in the links. Both the platens and the links were hardened enough to provide good strength and ductility while still allowing machinability. The press's hydraulic system was a 10,000 psi system with four cylinders pressing in parallel on a force concentrating cone. The system was designed to maintain preload in the event of a power failure.

The press was designed in coordination with six large buswork assemblies that carried current into and out of the magnet. The project included a lot of hours in the generator pit, preparing the hardware for firing and then cleaning up afterwards. Looking back, it was one of the most interesting programs I've been involved with. This project was managed by Mike Werst, who also did the mechanical design of the magnet; K.T. Hsieh did the mechanical & electromagnetic analysis, and Bob Sledge handled the buswork. The experiment and its test results were published in several papers at IEEE conferences.