Induction Motor Design with Reciprocating Rotor for Stirling Cycle Cryocooler

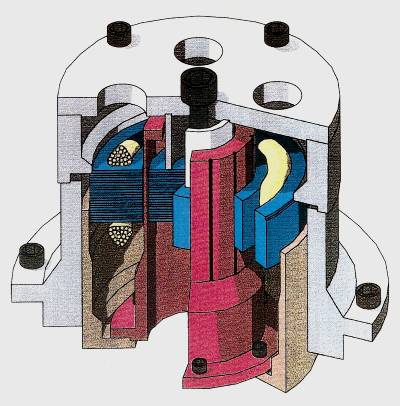

Sunpower had developed a free-piston Stirling cycle cryocooler that needed a gas bearing to keep its main piston from wearing within its cylinder. If the piston spun as it reciprocated, the hydrodynamic action (with helium as the lubricant) would keep the piston from contacting the cylinder. We had already built a brushless DC motor which spun the piston, but we wanted a motor with a lighter and cheaper rotor (the permanent magnets on the brushless DC rotor were heavy & expensive). So I proposed an induction motor for this machine. The rotor was a simple aluminum squirrel cage which could rotate & reciprocate in the airgap, and the outer & inner iron were stationary.

One of the mechanical challenges with this project was to make it assemble-able & serviceable. The rotor was a single piece of machined aluminum, to make it a simple robust component. The squirrel-cage itself was a radially thin section of the rotor, while the "endrings" of the rotor were thick sections just beyond the squirrel-cage. The cage had to spin within the narrow airgap, without the thick endrings striking any stationary parts during oscillation. The design required several concentrically fitting parts to be assembled in sequence. The motor was successful; it spun the main piston and created a non-contacting gas bearing. The design and its test results were published in a paper at the IECEC in 1989. The electromagnetics design was by Dr. Robert Redlich, the windings & inverter were by Scott McDonald, and the project was managed by Barry Penswick- it was a great team with everybody contributing something significant.