The Skew Corrugation Process

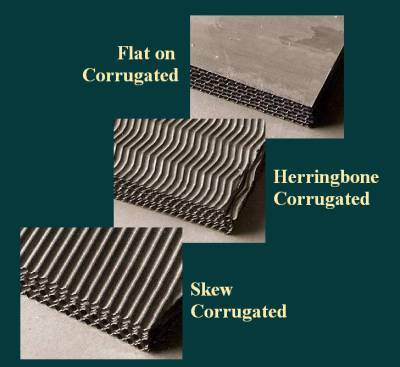

At Camet, a small company in Hiram, Ohio, we were in the business of making catalytic converters from corrugated metal foils. There were two ways to do this- The first way was the "flat-on-corrugated" approach, where individual pieces of foil were stacked up to make a matrix- these had low flow restriction because of their straight cells, but they were hard to make because they required stacks of many pieces of foil. The second way was the "herringbone" approach, where a metal foil was continuously corrugated with a herringbone pattern, then folded back & forth upon itself to make a matrix- these were inexpensive because they were very easy to produce by folding, but the herringbone pattern gave them higher flow restriction. If there was a process to corrugate straight cells at an oblique angle, the foil could be folded to produce an inexpensive matrix with low flow restriction.

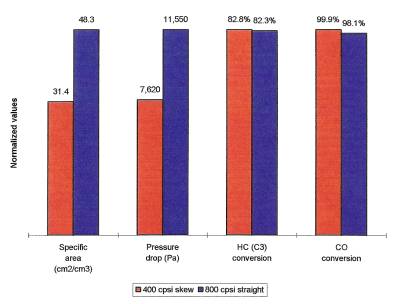

Skew corrugated samples were initially made using short pieces of foil. These samples were tested for pressure drop and catalytic activity, and the results were compared with flat-on-corrugated samples. The data at left shows that a skew sample, using ~35% less foil than a flat-on-corrugated sample, has ~35% lower pressure drop while delivering a slightly better catalytic activity. This was one of those rarities in engineering- a surprisingly good test result. A skew corrugated matrix would not only be easy to make and use less foil, but it would be a better catalyst than its flat-on-corrugated counterpart.

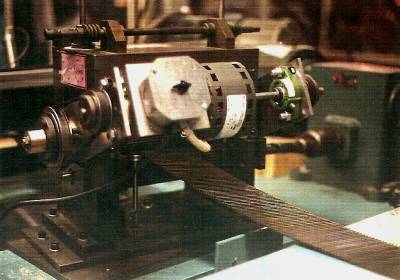

To make a continuous skew process, I conceived of a corrugating gearset that combined rotary & oscillating motion. Rotation would corrugate the foil, while oscillation would allow the foil to slip along the gears and reset itself into a steady track, thus making the process continuous. A proof-of-principle mechanism was built and tested (successfully). This work was the subject of my MSE design project at CWRU. The process is documented in U.S. patent 5,735,158.

Skew corrugated foil was used in various catalysts- typically in round monoliths for automotive or small engine use. We devised ways to package the skew cores into cans- see patent 6,066,228 with Bryce Zoccola. Camet became a small division of W.R. Grace, then a division of Engelhard, then Engelhard was acquired by BASF. BASF currently markets skew products under their Camet® trademark.