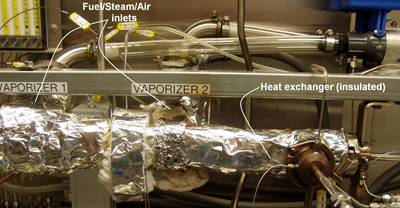

High-temperature foil-based heat exchanger

Two grant programs (NSF & State of Ohio) were awarded to Catacel to develop a high-temperature, inexpensive heat exchanger "platform" (HEP). The device was small enough to be arranged in modules to form larger heat exchangers without the need for a lot of custom design & construction. Because it had to withstand temperatures up to 900°C, the HEP was made from oxidation-resistant stainless & nickel alloys. To keep costs down, most of the heat exchanger structure was made from thin foil; the foil was formed into an accordion shape and then furnace-brazed with cover sheets and thicker sheet metal ducts.

It was quickly evident that the biggest challenge for the HEP was the brazing process. State-of-the-art brazing companies reported that the thinnest foils brazed in production were 0.007" thick. We, however, were planning to build the HEP with 0.004" foil, and this seemingly insignificant difference created challenges. We found that the HEP foil components had to be treated as close-fitting sheet metal parts (because they were)! The components had to be very accurately cut & formed on precision tools. We developed many trade secrets to insure that the brazing process created the required hermitic seal without eroding through the thin foil. The HEP was successfully qualified through a 1000-hr cyclic life test and the design was protected under a patent. An accurate model of the heat exchange characteristics was empirically built from an exhaustive series of tests.

The HEP was designed not only to be modular, but flexible in its application. The freshly-brazed HEP was a "shell" into which different foil inserts could be installed. These inserts could also be coated with a catalyst- thus the HEP could exchange heat to drive different chemical reactions. An NSF program funded us to demonstrate a 100-hr cyclic run of an HEP with one side acting as a combustor which would (thermally) drive the other side to act as a fuel reformer. Every several hours, the functions would be flipped- the combustor would turn into a reformer, and vice versa. Luckily, Catacel has a dream-team of innovative individuals that I worked with to bring the HEP to fruition. John Becker, Lorne DeYoung, Todd Romesburg, Dave Becker, Dave Brunelle and Bill Whittenberger all contributed bold ideas, tireless labor & many years of experience.