Development of EHC's

At Camet, a small company in Hiram, Ohio, we developed several generations of foil-based Electrically Heated Catalysts (EHC's), designed to achieve rapid liteoff for cleaning up exhaust from cold-starting engines. The EHC took electric current from the car's battery & generator to heat catalyst-coated foil leaves to ~700°C in a matter of seconds; the EHC was positioned upstream of the main catalyst. This program fit nicely with Camet's existing product lines (catalysts based on corrugated metal foils). After startup, the EHC had to go on to survive the brutal environment of the automotive exhaust stream, so durability was a significant design challenge.

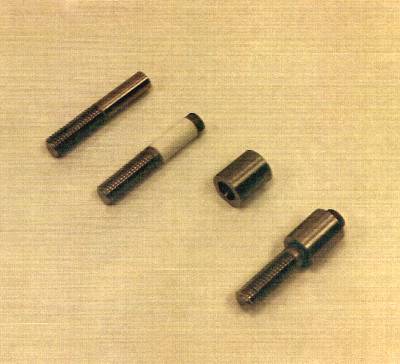

Another challenge of EHC design was the power feedthrough. It had to carry up to 500A and tolerate the high-temperature cyclic environment without leaking. Tom Sheller, a Camet engineer, had experimented with concentrically fitting cans using a ceramic plasma coating for electrical insulation. The plasma coating would resist the high temperatures present on the EHC. I built on Tom's idea, using a plasma-coated stud that was ground to size, then press-fit into a stainless collar. The design was very robust (it withstood 500-hr temperature cycling tests to 900°C) and became a standard feature of our EHC's. The design is documented in U.S. patent 5,238,650.

Our first EHC's were heated throughout- current passed through every foil leaf. The standard coatings could be used to insulate the leaves from each other- but heating the entire matrix consumed a lot of power. After test results indicated that only the upstream face of the matrix needed to liteoff (inducing the downstream portion to subsequently liteoff), we designed EHC's with thin heater leaves woven into the front face. Special refractory coatings were developed to insulate the heater leaves from the rest of the matrix. Later, the heater strips were designed with periodic holes in them; this created a spot-heating pattern only on the front face of the matrix. This was the most efficient use of electric power to lead a catalyst to rapid liteoff. Eventually the program was displaced by the development (elsewhere) of better main catalysts and engine controls; the more stringent emissions targets could be met without an EHC, so we all moved on to other programs.